engineering & technology publications

ISSN 1759-3433

PROCEEDINGS OF THE EIGHTH INTERNATIONAL CONFERENCE ON COMPUTATIONAL STRUCTURES TECHNOLOGY

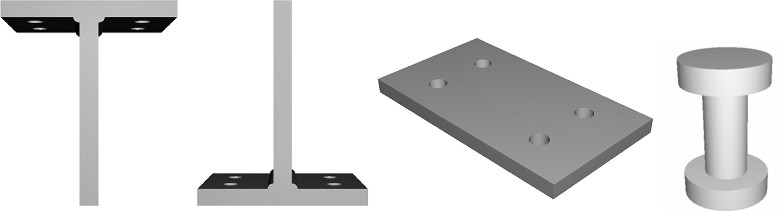

Numerical Analysis of Welded Aluminium T-Stub Joints under Monotonic Loading

1Department of Structural Analysis and Design, University of Naples "Federico II", Italy

2PRICOS, Architectural Faculty, University "G. d'Annunzio" of Chieti/Pescara, Italy

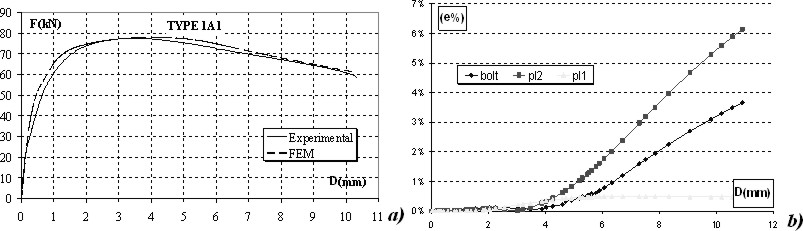

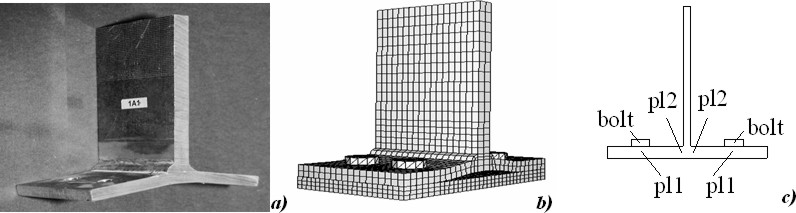

The comparison with the available experimental results has shown the adequacy of the numerical model, which is able to reproduce correctly the mechanical response and reliability of the joint, as well as to provide a correct interpretation of the related collapse mechanism in all cases examined (see Figures 2 and 3).

|

The experimental results obtained have also been compared in terms of the collapse load to the ones derived from the application of the analytical procedure provided in the final version of EC9 [3]. The comparison underlines that the codified method is significantly conservative and a reduction of the related scatter can be obtained through a more precise evaluation of the effective width of the equivalent continuous beam, by means of the results achieved through the proposed numerical model. Therefore, it has been demonstrated that, when the codified procedure is applied taking into account such an effect, the mean scatter reduces to about 5%.

- 1

- Hibbitt, Karlsson, Sorensen, Inc., "ABAQUS/Standard", version 6.4, Patwtucket, RI, U.S.A., 2004.

- 2

- De Matteis G., Mazzolani F.M., "Behaviour of welded aluminium T-stub connections: experimental analysis and interpretative models", Proc. of the ASCE Structures Congress 2006, St. Louis, Missouri, U.S.A., May 2006.

- 3

- De Matteis G., Mandara A., Mazzolani F.M., "Design of aluminium T-stub joints: calibration of analytical methods", Proc. of the Third European Conference on Steel Structures, Coimbra (Portugal), Vol. II, 1017-1026, 19-20 Sept, 2002. doi:10.1061/40889(201)45

purchase the full-text of this paper (price £20)

go to the previous paper

go to the next paper

return to the table of contents

return to the book description

purchase this book (price £140 +P&P)