engineering & technology publications

ISSN 1759-3433

PROCEEDINGS OF THE FIFTH INTERNATIONAL CONFERENCE ON ENGINEERING COMPUTATIONAL TECHNOLOGY

Neural Network Based Genetic Algorithm Optimization of Hat-Shaped Beams

Department of Structural Engineering, Budapest University of Technology and Economics, Hungary

The first phase of the research is to develop a design process based on nonlinear finite element simulations in parallel with laboratory tests [1]. In the second phase of the research the purpose is to develop a neural network (NN) to predict the ultimate load of the hat-shaped beams using virtual and the real test results. By the trained neural network the ultimate load can be determined very fast, which can be the basis of a genetic algorithm (GA) based optimization process in the third phase of the project.

The paper has a focus on the second phase of the research, where NN-based GA-optimization of hat-shaped beams is carried out on hat profiles without holes in the web, with the resistances given by Eurocode 3.

To predict the load bearing resistance of the member a backpropagation neural network is developed with one hidden layer, sigmoidal activation functions in the hidden layer and a linear function in the output layer. The input parameters of the network are the geometrical data of the cold-formed hat-section. As output data the resistances for four different statical systems, calculated according to the standard, are considered. The number of nodes at the input, the hidden and the output layer are 4, 8 and 4, respectively. The trained network is used to find the optimal section geometry for different member lengths and statical systems using a genetic algorithm.

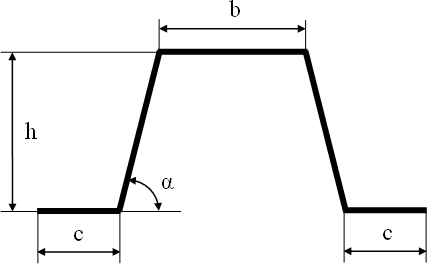

The design variables, the height of the section, h, width of the flange, b, the

depth of the lip, c and the angle of the web ![]() , are shown in Figure 1. Other

parameters using for the calculation, such as thickness, the internal radius of the

corners and the material properties are fixed during the optimization.

, are shown in Figure 1. Other

parameters using for the calculation, such as thickness, the internal radius of the

corners and the material properties are fixed during the optimization.

The current optimization problem is defined as:

| Maximize |

(69) |

where

The optimization is carried out for different statical systems. It is shown that the NN-based GA-optimization is well applicable to optimize the cross-section geometry of cold-formed steel members, since the difference in the load bearing efficiency of the section is insignificant (under 1%) in all investigated statical systems.

Since the neural network gives results very fast, the method presentedseems to be well applicable based on finite element simulations.

The research project continues with a detailed analysis of the optimum cross-section varying the length of the span and the cantilever. In a parallel investigation the effect of material properties on the optimal dimensions is also planned. The final step is applying the approach with virtual experiments.

- 1

- D. Honfi and L. Dunai, "Experimental and Numerical Investigation on Hat-Shaped Beam Members with Hole in the Web", International Colloquium on Stability and Ductility of Steel Structures, Lisbon, Portugal, 6-8 September 2006 (to be published).

- 2

- ENV 1993-1-3 "Eurocode 3: Design of Steel Structures - Part 1-3: General Rules - Supplementary Rules for Cold-Formed Thin Gauge Members and Sheeting", CEN, Brussels, 1996.

purchase the full-text of this paper (price £20)

go to the previous paper

go to the next paper

return to the table of contents

return to the book description

purchase this book (price £105 +P&P)